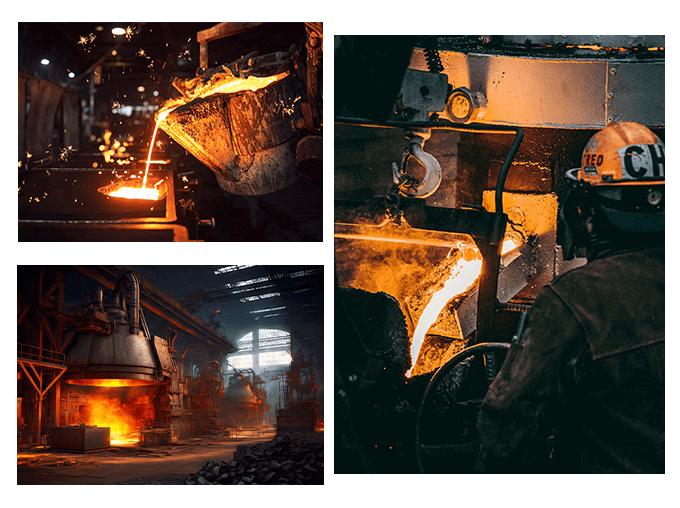

MI Metallurgy+ is formulated using nano carbon and nano silicon particles to de-oxidize & to remove oxygen and metallic oxides in liquid steel melts.

| Specifications | % Be | % Si | % C | Size (mm) |

|---|---|---|---|---|

| MI METALLURGY+ (Barium Base) | 3-5% (Barium) | 45-55 | 30-40 | 0.5 to 10.0 (Any Spec) |

| MI METALLURGY+(Sodium Base) | 5% Max (Sodium) | 45-55 | 30-40 | 0.5 to 10.0 (Any spec) |

MI DeCarb is a specially designed and engineered product by our in-house R&D team to reduce carbon in liquid steel melts.

MI DeCarb is added to the liquid steel in the furnace

It is added into the liquid metal 10 minutes before tapping

Defending on the percentage of carbon reduction, the addition will vary

A powerful collapsible agent to weaken the surface tension forces of Sodium Silicate bonded CO, sand moulds / cores thereby allowing for easy breaking of the cores/moulds.

Copyright ©2024 Metgroup. Designed By Webomindapps